Popular Posts

-

Disney cars Disney Cars Saly Filmore Disney Cars coloring pages wallpaper Lightning Mcqueen Ramone disney cars poster

-

2013 Cars Model, 2013 car, photo mercedes, car dekho, car electric, new cars, new vehicle, cost of cars...

-

Red And Black Ferrari Car Red Ferrari Car Wallpaper Yellow Ferrari Car Picture Latest Model Ferrari Car Pink Ferrari Car Wallpaper

Tuesday, February 28, 2012

Solidworks Drawing Views and Associativity

Thursday, February 16, 2012

How to submit an Enhancement Request for SolidWorks

Thursday, January 26, 2012

A Green Street Machine? Foden Designs Use SolidWorks Sustainability to make the unheard of a Reality

- Keeping design and manufacture to a budget

- Ensuring the design and manufacture are sustainable with minimal environmental impact

- Being able to design and manufacture within short time frames to meet customer demand

- Flexibility in allowing rapid changes from one material/manufacturing technique to another

- Ability to analyse material changes and their impact on costs and sustainability in a matter of minutes

- Savings in both time and money

- Being able to measure environmental impact

- Working within client budget constraints

- Outsourcing all of our projects to have someone else do the analysis

- Hiring a new staff member to do the research and analysis for the project or;

- Finding the software to allow our current designer to do the analysis internally

Tuesday, January 24, 2012

Solidtec Solutions announces increased value to Subscription customers with free Web Technical Training

Our new Solidtec Webtec technical web training courses are designed to enable our customers to get the most from their SolidWorks 3D CAD solution with a practical, hands on approach to training.

Solidtec Webtec will be free for all Solidtec Subscription Service customers in Australia and New Zealand and will be offered in the following categories:

SolidWorks Web Training

Solidtec delivers these monthly technical web training sessions to their Subscription customers to demonstrate how SolidWorks can solve design problems and to introduce new modelling and detailing techniques and methods. Attendees can interact live with the presenter and are encouraged to submit topics, problems and models that can be covered in case studies in future sessions. These sessions will be facilitated by Stewart Nankivel who has over 15 years’ experience in SolidWorks technical training.

Simulation Web Training

Simulation technical training sessions are aimed at existing Simulation users wanting to increase their knowledge and confidence in SolidWorks Simulation. This online training is interactive providing attendees an opportunity to ask questions and even submit problems and models to be covered in future sessions. With the introduction of this free monthly technical training, Solidtec Solutions will bring together the SolidWorks Simulation Community in Australia and New Zealand by providing a forum where users can interact and share their Simulation knowledge. These sessions will be facilitated by one of the few Certified Simulation Premium and Flow Simulation Professionals in ANZ, Solidtec's Elite Application Engineer and in-house Simulation expert, Damien Murphy.

“Solidtec Solutions is committed to adding value to our customers through initiatives such as Solidtec Webtec so they increase their profitability and innovation and benefit from the knowledge and experience of our technical experts and the ANZ SolidWorks community” said Gareth Hudson, Solidtec Solutions Technical Services Manager.

Wednesday, January 18, 2012

How to Upgrade your Solidworks installation

To jump directly to the instructions, click here.

If you would like to run two major versions of SolidWorks (e.g. 2011 and 2012) alongside each other, click here.

It is not necessary to uninstall and reinstall between Service Packs, only major releases (i.e. each year). To learn how to update your SolidWorks version (e.g. go from SolidWorks 2012 SP1 to SP2) click here.

This is not intended to be a step-by-step installation guide and assumes some familiarity with basic computer maintenance, etc. If at any stage you are unsure of how to proceed, please contact your Solidtec Application Engineer.

The steps below are for standalone SolidWorks licenses. To check if you have a standalone license, from SolidWorks go to the Help menu. If you have the option to "Transfer license", you have a standalone license. If you have a network (SNL) license, most steps will be the same. If unsure, contact your Solidtec Application Engineer.

Contents

- Before you begin

- Uninstall the old version

- Install the new version

- After installation

- Further information

Before you begin

- Back up any local data. We recommend keeping a copy of your data in the old format should you need it. More information on backups can be found here.

- Make a note of any SolidWorks customisations, such as keyboard shortcuts. From SolidWorks >> (start a new Part if none are open) >> Tools >> Customize >> Keyboard tab >> check "Show only commands with shortcuts assigned" >> Copy List. This will copy the settings to the Windows Clipboard and you can then paste them into Excel or Notepad, etc. Although this requires you to re-input your keyboard shortcuts after reinstalling SolidWorks, there is no risk of "contaminating" the Registry settings. Do not use Copy Settings Wizard, as it copies the entire SolidWorks registry and can cause problems with the new version.

- Copy the SolidWorks Serial Number. From SolidWorks >> Help >> About SolidWorks. Make a note of the Serial Number (copy to Notepad or write it down on paper, etc.) - you may need to re-enter it during installation later on.

- Transfer the SolidWorks License off the machine. This ensures your license is available to use on another computer if anything happens during the uninstall/reinstall process. From SolidWorks >> Help >> Transfer License. If you are having trouble connecting to the SolidWorks License Server, make sure that internet traffic is allowed to/from https://activate.solidworks.com/

- Make sure you are logged in to Windows as an administrator. If you are unsure, see http://www.computerhope.com/issues/ch001093.htm

- Uninstall SolidWorks. Start Menu >> Control Panel >> Programs and Features (Add/remove programs in WinXP) >> SolidWorks >> Uninstall. The SolidWorks 2011 Installation Manager will start.

- If you are uninstalling SolidWorks 2011, right-click on the title-bar (up the top, where it says "SolidWorks 2011 Installation Manager") >> Total Uninstall >> proceed through the IM process (keep clicking Next).

- If you are uninstalling SolidWorks 2010 or earlier, please read the end of this post regarding how to clean your registry. It is important to do this to ensure the smooth opertation of the new version.

- Once uninstalled, reboot the computer.

- THIS IS A CRITICAL STEP! Disable any Anti-virus programs that are running as these can interfere with the installation process. Some Anti-virus programs are very difficult to disable – if in doubt Google for instructions “disable < Anti-virus Program Name>”.

If required, you can generally disable anti-virus programs manually:

- Start >> Run >> Control Panel >> Administrative Tools >> Services.

- Find all relevant anti-virus services >> RMB >> Stop

- Once installation is complete >> RMB >> Start

- Insert the SolidWorks Media Disc (make sure it is the correct bit version - 32 and 64-bit versions are supplied in the box). If the Installation Manager does not start automatically, browse to the media location in Windows Explorer and RMB on Setup.exe >> Run as administrator to begin installation.

- Run through the Installation Manager. If the Installation Manager detects the previous install, it may ask you to upgrade - this is fine, proceed as normal.

- Installation type is Individual.

- Enter the Serial Number if prompted (enter extra Serial Numbers if installing Simulation Premium or Flow Simulation).

- If you have SolidWorks Professional or Premium, click here to read about installing/upgrading the Toolbox.

- If you transferred the license off the computer previously, or there was no license on the machine, when starting up SolidWorks you will be asked to activate the product. Run through the process, using correct contact details (these will be associated with the Serial Number). If you are unable to activate, use the 30-day Trial Activation. This will give you access to SolidWorks Premium for 30 days regardless of what version of SolidWorks you are entitled to. If this happens please notify your Solidtec Application Engineer

- Make sure that the File Locations are set up correctly if using a central file server. From within SolidWorks >> Options >> System Options tab >> File Locations. The most common locations to change are: Document Templates, Sheet Formats, Weldment Profiles and Custom Properties. To add a Custom Properties location you may need to delete the existing location first (SolidWorks can only handle one location for the Custom Properties file).

- Apply any customisations, such as keyboard shortcuts, toolbar layouts, etc. Back these settings up using the Copy Settings Wizard.

- Consider creating a Disc Image of your HDD, to allow for quick restoration to a known clean install state. Click here to read more.

- If you have SolidWorks Professional or Premium with the Toolbox add-in, the correct method to update the Toolbox data is as follows:

- Browse to your existing (e.g. 2011) Toolbox data folder - by default this is in C:\SolidWorks Data.

- Copy the folder and its contents - rename the copied folder something like "SolidWorks Data 2012". Make another copy of the orignal folder and keep it with the rest of your backed up SW2011 data.

- During installation, on the Summary page under Toolbox Options >> Change. Choose to "Upgrade an existing Toolbox location" and browse to the "SolidWorks Data 2012" folder. Continue the installation process.

- This will upgrade the contents of the new folder, leaving the previous folder intact if you wish to continue using SolidWorks 2011. If you do not need the 2011 data anymore, you can delete the orignal "SolidWorks Data" folder.

- If you have already installed SolidWorks and need to change the location of the Toolbox from the default local installation path to a file server path, from within SolidWorks >> Options >> System Options tab >> Hole Wizard/Toolbox >> Browse to the correct location.

Uninstall the old version

Install the new version

After installation

Setup

Toolbox installations

Further information

Further information on installing SolidWorks can be found here:

- SolidWorks Installation and Admin Guide – the official Admin guide.

- How to ensure a clean uninstall and update of SolidWorks – a more involved method of preparing your machine for a clean SolidWorks installation.

Tuesday, January 10, 2012

How to install Multiple SolidWorks versions on one Computer

The method used will help keep the file references between the two versions apart.

Thursday, December 1, 2011

How to Activate and Transfer a SolidWorks Stand-alone license

Tuesday, November 22, 2011

Part number generator macro for Solidworks

Tuesday, November 8, 2011

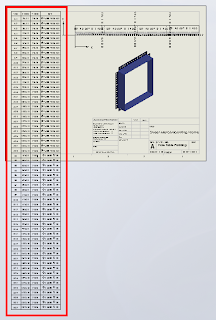

Hole Table Padding - Adjusting beyond the standard limits

Pic_1: The Problem

Before we continue, remember that we can only fit so much on to a single sheet before it becomes unreadable, so there is obvioulsy a limit to how many rows you will be able to fit vertically on a specific sheet size.

Click anywhere in the table to activate its properties. You will see this dialogue appear above the table:

Note where the adjustment settings are for Font Size and Vertical Cell Padding. We'll get back to that in a second.

Next, click on the number 2 to select the entire row. Hold down the Shift key and select the last row in your table (I had sixty rows all up in this example). You should now have all rows except the heading row selected. With all rows selected you can change your font size; I have used 9, which is still quite readable and then we want to adjust the Vertical Cell Padding.

You will note though, that when you dial down (using the up-down arrow toggles) you will be stopped at zero. Naturally you will think this to be the limit, but alas, we know with Solidworks anything is possible. Simply select the Vertical Cell Padding field as below...

And while we are at it, quickly click anywhere in the table, then click the black cross to the left of Column A to activate the table properties dialogue, which will appear to the left of your screen. We want to tidy things up a little before printing. In the properties dialogue select "Combine same sizes" and you will get this:

In the properties dialogue, click the green check mark to close and we're done.

You should now have your table fitting nicely onto your drawing sheet and looking much better than when we started.

Have a play with those settings and I hope that this has helped you somewhat to tidy up those Hole Tables.

Tuesday, October 11, 2011

How to place a point at the Center of Mass

Sunday, August 7, 2011

Solidtec Solutions Help REYN Consultants Save Design Time

Tuesday, July 5, 2011

SolidWorks Simplify Tool

For more SolidWorks tips & tricks, please visit the Solidtec Blog.

http://solidtecsolutions.blogspot.com/

Wednesday, June 29, 2011

How to model a Fancy Tube in SolidWorks.

Thursday, June 23, 2011

Solidworks Mass Properties And Solid Body's

Followers

Category

- Alfa Romeo

- Aston Martin

- Aston Martin Sport Cars

- Audi

- Audi Sport Cars

- BMW

- BMW Concept Cars

- BMW Sport Cars

- BRABUS Sport Cars

- Bugatti

- Cadillac

- Camaro

- Cars

- Chevrolet

- Chevrolet Sports Cars

- Chrysler

- Citroën

- Concept Car

- Design Car

- Electric Car

- F1 Car

- Fast car

- Ferrari

- Ferrari Sport Cars

- Fiat

- Ford

- Ford Mustang

- Ford Sport Cars

- Green GT

- Hamann

- Honda

- Honda Concept Cars

- Honda Sport Cars

- Hybrid Car

- Hybrid Sports Cars

- Infiniti

- Jaguar

- Jaguar Sports Cars

- Kia

- Koenigsegg

- Lamborghini

- Lamborghini Cars

- Lexus

- Lotus

- Luxurious Sports Car

- Luxurious Sports Sedan

- MazdaSpeed 3

- Mercedes

- Mercedes-Benz Concept Cars

- Mercedes-Benz Sport Cars

- Nissan

- Nissan Concept Cars

- Nissan Sports Cars

- Pagani

- Peugeot

- Porsche

- Porsche Sport Cars

- Race Car

- Racing Car

- Renault

- Roadster

- Sport Car

- Sport Cars

- Sports Car

- Sports Saloon

- Sports Sedan

- Super Sports Cars

- Supercars

- Toyota

- Venturi

- Volkswagen

- Volkswagen Sports Cars

- Volvo

- Volvo Sport Cars

- Wiesmann Sport Cars

- Wings of Nike